Hubung Case Study for P&A using HWU Rev 0

Hubung : Real-Time Monitoring System

Redefine HWU Performance for

P&A Activities in Penisular Malaysia

Challenges

- Inaccurate operating data and delayed information

- Limited data-driven decision-making

- Unable to verify tripping speed, cement volume, and integrity

- No visual recording for safety monitoring at the site

Solution

- Comprehensive Sensor Deployment: Advanced sensors strategically installed at critical locations for seamless data acquisition and real-time operational insights.

- Real-Time Monitoring System: A robust workstation equipped with real-time monitoring software installed at both the DSV site office and the remote town location, ensuring continuous, real-time visibility into operations.

- High-Definition ATEX-Certified Surveillance: Six ATEX compliant cameras installed at key operational areas.

- Integrated Visual Display: Monitors installed at the DSV site office and the town facility, offering synchronized real-time data and video feeds for enhanced operational control and situational awarenes

Adversity Path

Petrogroup was contracted to provide Video Monitoring Systems (VMS) and Data Acquisition Systems (DAS) for the Plug and Abandonment (P&A) operations at the Peninsular Malaysia platform. The primary objective was to enhance safety, improve operational oversight, and provide real-time data for decision-making and performance optimization during the P&A process. The current practice is manual logging of data, analogue data capture by human-eye or pictures. These data then were sent to project team via email. Due to the nature of Plug & Abandonment campaign, data was not captured digitally as what usually a common practice in Drilling through Mudlogging and MWD Data. This impact the operational efficiency of HWU operators.

Currently, HWU operators were limited with the use of conventional electronic document management and reporting tools for analytics which did not provide enough detail for accurate analysis and is only as good as what is entered. Much of their work was manual. For example, Currently, the company’s joint and tripping speed during POOH (pulling out of hole) and RIH(running in hole) is determined manually through tally sheets and Drilling Operation Reports (DOR), which introduces human error and inefficiencies due to the lack of real-time sensor-based analysis.

Deliverable

- Project completion 20 days ahead of schedule Average well completed in 9 days compared to 15 days during planning stage

- Achieve optimum tripping speed as per HWU capability of 15 joint per hour

- Cost saving approx. Myr 15 million due to project completed early ahead schedule.

- 28% improvement in operational efficiency

- Daily invisible lost time detection by operation

The Resolution Point

Petrogroup offers video management system and data acquisition system for HWU that can help well construction companies address their needs in real time monitoring and daily invisible lost time detection by operation dashboard and improve operational efficiency by 28%.

Enhanced Operational Precision Through Integrated Video Monitoring for HWU in Plug & Abandonment

The Video Monitoring System enabled continuous oversight and reporting of operations from HWU instrumentation, significantly enhancing visual data quality. Video feeds was mean for quality assurance, ensuring consistent monitoring across all critical operations. Video data from multiple sources was then consolidated intoone platform, a first for this Operator. By integrating real-time visual data from both surface and subsurface operations, the P&A and well services teams collaborated more effectively, improving operational precision, reducing downtime, and optimizing the overall Plug and Abandonment process. This enhanced inter-departmental collaboration was instrumental in driving efficiency and safety improvements.

KPI analysis reveals opportunities for improvement

The integrated system’s analytics provided a comprehensive view of key performance indicators (KPIs), such astrip efficiency, tripping speeds during Pull Out of Hole (POOH) and Running In Hole (RIH), and equipment utilization rates. For the first time, the Operator could compare detailed time breakdowns for cementing, tagging, and testing operations across multiple well sites. This allowed the team to identify bottlenecks, optimize tool deployment, and reduce non-productive time (NPT), ultimately leading to more efficient well abandonment procedures and improved operational safety.

This analysis became an enabler and integral part of the contractor’s service quality meetings and helped the Operator to evaluate HWU performance. Insights and Analysis: The end-of-well reports were essential for evaluating the efficiency of the operation, identifying areas for improvement, and ensuring data integrity forfuture reference.

The Output

The combination of daily and end-of-well reports played a pivotal role in maintaining high levels of operational oversight and transparency. These reports not only ensured the accurate monitoring of key metrics but also facilitated continuous improvement throughout the project. The insights derived from these reports supported.effective decision-making and set a benchmark for subsequent projects.

Constant monitoring leads to performance insights

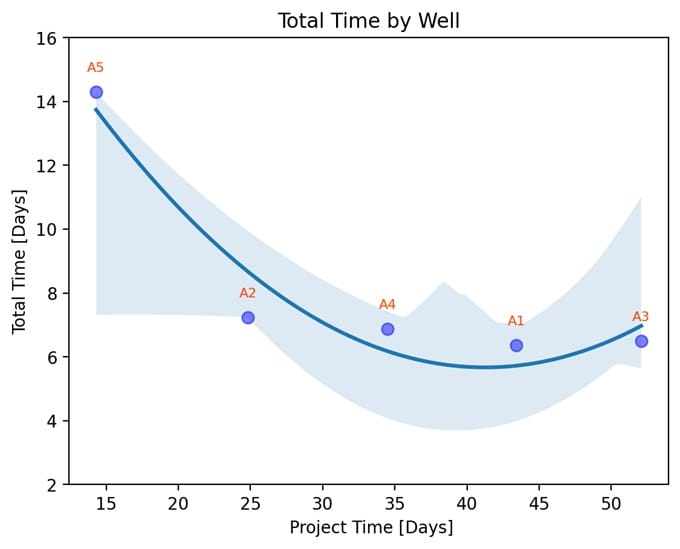

One of the biggest improvements during this project was in data quality. Well time are calculated as the difference between the first and last joint of each well The plot shows that the project achieves a good performance after the second wells and continue improving until the last well.

Optimized Tubular Handling Enhancing Efficiency in Plug and Abandonment Operations

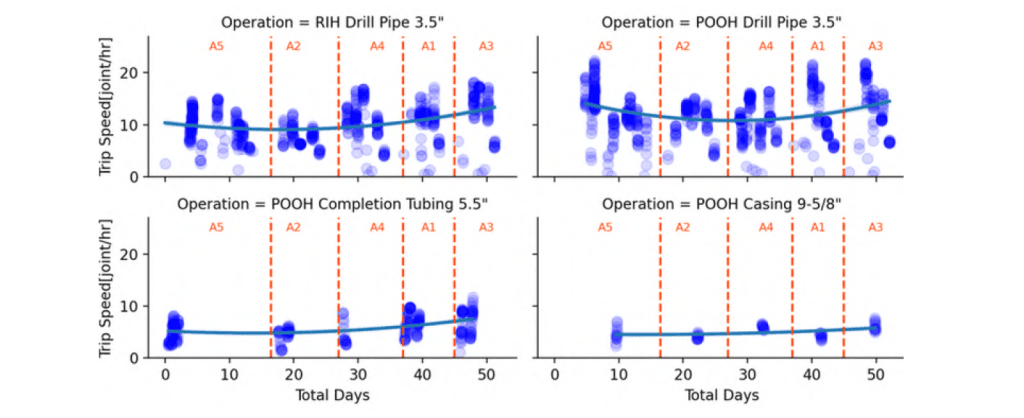

Another example of a positive operational impact was the result of a study done on connection times. In theseplots can be noticed a continuous improvement performance in in handling 3 1/2″ drill pipe trips, both in POOHand RIH activities. An excellent learning curve can be seen retrieving completion tubing showing continuousimprovements from well to well along the project.

Automation Through Hubung/Data Acquisition System Transforms P&A Operations with Real-Time

Insights

With the implementation of the Hubung by Petrgroup, the Operator saw a significant transformation in Plug and Abandonment (P&A) operations. Previously, manual recording of operational data made it time-consuming to analyze key metrics. Now, with automated data capture and real-time analysis, the system provides immediate insights into tripping speeds, pressure tests, and cementing operations. This automation reduced the time spent on manual data entry and allowed engineers to make faster, data-driven decisions, optimizing the P&A process and improving overall operational efficiency.

Vision Path

Going forward, the Operator will be implementing this solution in other business units, making it a model for optimizing operations. There are plans for opening a 24×7 operations center intended to positively change the operator’s work culture for the planning, execution and evaluation of the HWU rig performance.