Maintenance Division Services

Mechanical maintenance involves the systematic inspection, servicing, and repair of machinery and equipment to ensure reliable and efficient operations. This critical function aims to extend equipment lifespan, prevent failures, optimize production, and uphold safety standards

Compliance with Industry Standards:

Inline X is designed and developed with a focus on meeting industry standards and best practices, including API 576 and ASME PTC 25. These standards provide guidelines and requirements for PSV testing, ensuring safety, reliability, and regulatory compliance.

Methodology Adherence:

Inline X follows the recommended methodologies and procedures outlined in API 576 and ASME PTC 25 for in-situ testing of PSVs. It takes into account factors such as test pressures, test durations, measurement accuracy, equipment requirements, documentation, and reporting, aligning with the fundamental principles set forth in the standards.

Documentation and Reporting:

Inline X facilitates comprehensive documentation and reporting of the in-situ pressure testing process. It captures essential data points, test parameters, and test results, enabling thorough documentation in accordance with API 576 and ASME PTC 25 requirements. This ensures traceability and auditability of the testing process.

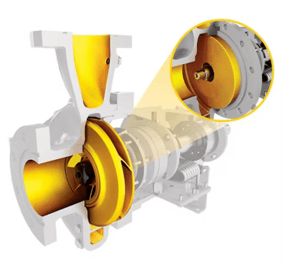

Conforma Clad

Our company, in collaboration with our esteemed partner, proudly provides Conforma clad for rotating and fixed equipment. For rotating equipment and fixed equipment utilized in petrochemical and refining applications, Conforma Clad™ offers both Stellite™ and tungsten carbide cladding solutions. The Conforma Clad process produce

- cladding microstructure is consistent throughout

- cladding has minimal porosity

- cladding has a strong metallurgical bond (>70,000psi)

- cladding can be used in operating temperatures up to approximately 1850⁰f

- cladding can be applied complex geometries, inside diametetors, and other non line-of-site surfaces that are unreachable by other methods.

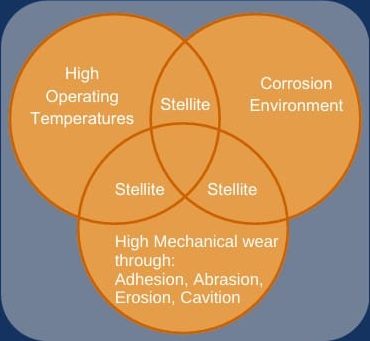

Stellite materials outperform other material

options when at least two of the following

present:

- High Operating Temperature

- Corrosion

- High Mechanical wear

Our experienced metallurgist and

applications engineer are here to help!

Application Sample

FIXED EQUIPMENT

ROTATING EQUIPMENT

Extending the life of rotating equipment involves proactive maintenance, condition monitoring, and strategic upgrades to mitigate wear and tear and prevent premature failure. Key strategies include proper lubrication, keeping equipment clean, managing temperature, and addressing misalignment or vibration issues